1. Never Start The Engine Out Of Water

Never start the engine out of water, even if it’s only for a few seconds. Water-cooled engines will heat very quickly when started in the open air, which can lead to premature wear of seals, gaskets and other components. If you need to run the engine out of the water, use a flushing kit to protect the engine from rapid heating.

Always use an engine flush kit if you need to start your engine out of water. Neglecting to do so can result in damage and expensive repairs.

2. Don’t Over-Rev the Engine

Every engine is designed to operate within a specific range of rpm. Running the engine above that range will reduce its life. Check your owner’s manual to ensure the boat is running at the correct rpm when you operate at full throttle. If it runs higher than it should, change your propeller to one with a slightly higher pitch and lower full-throttle rpm into the recommended range.

3. Install a Water Pressure Gauge

While the stream of water flowing from your outboard may look fine at a casual glance, have a water pressure gauge installed so you can confirm the engine is getting enough water to properly cool itself while underway. The water passages inside the engine can clog over time, reducing water flow and cooling efficiency. With a simple and inexpensive gauge, you can quickly determine if there’s a problem, and fix it before suffering serious damage.

4. Replace Damaged Propellers

Small nicks and dings in the propeller can create vibrations that will ultimately shorten engine life. Check your propeller regularly, and fix damage to propellers promptly.

Even tiny nicks and gouges in the propeller will induce vibrations which will result in premature engine wear. Remember – your engine is built to tolerances measured in thousands of an inch, so it will be sensitive to vibrations you won’t even feel. Always check your propeller carefully after every use, and have small nicks and chips repaired at once.

5. Watch the Temperature Gauge

The worst thing you can ever do to an engine is to overheat it. If your boat doesn’t come with an engine temperature gauge, have one installed. This inexpensive investment can save you thousands of dollars in engine repairs.

6. Change the Oil

We change the oil regularly in our vehicles, but amazingly many boaters forget about this crucial task. Because many smaller boats don’t come with hour meters, it’s easy to lose track of how long it’s been since the last oil change. Either install an hour meter or keep track of engine hours in a log book, so you always know when you’re due for a fluid change.

7. Replace Filters

While we usually replace the oil filter with every oil change, it’s important to replace all of the filters in your engine regularly. That includes fuel filters, air filters, and strainers on the water intakes, for example. Overlooking these vital components will reduce engine life. Always follow the replacement schedule as outlined in your owner’s manual.

8. Clean the Engine

Engines ingest all sorts of debris that can collect inside, reduce performance, and ultimately lead to premature wear. Even seemingly inert things like pollen and algae can accumulate and cause problems, either by blocking internal passages or by coating the engine’s exterior surface and holding in heat. A regular cleaning eliminates that threat. Further, a clean engine makes it easy to watch for any fluid leaks that could lead to costly problems down the road, and allows you the opportunity to perform a regular visual inspection of components like cooling hoses and belts, which are essential for proper operation. Replace any that are beginning to crack or feel mushy.

9. Buy Good Gas

Many engine problems can be attributed to the regular use of low-grade fuel. Most marine engines are designed to run with 87-octane gasoline with a maximum of 10% ethanol. The recent move to adopt 15% ethanol can result in premature wear of gaskets, seals and other soft compounds, so avoid fuel with 15% ethanol to prevent premature wear. Upgrading to 89-octane fuel can provide benefits – the engine will burn it more completely, reducing carbon deposits and guarding against long-term damage caused by substandard gas.

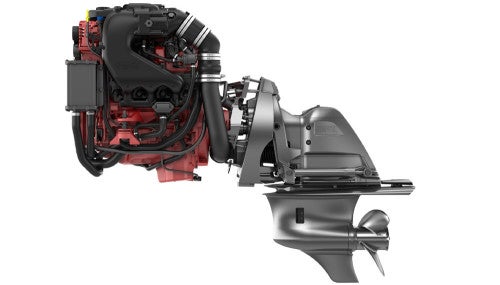

10. Check the Gearcase Lube

One of the most common problems with stern drives is gear damage resulting from water leaking into the gearcase. That’s why it’s imperative to check the gearcase lubricant on a regular basis. Open the lower drain plug and let a few drops of the liquid drain out into a pan. If you see any evidence of water mixed in with the lubricant, you have a leaking seal that needs to be replaced promptly. Running the engine will result in damage to the gears, and turn a fairly simple repair into a much more expensive one.

Fort Lauderdale International Boat Show Preview

Fort Lauderdale International Boat Show Preview 10 Best New Boat Accessories at IBEX 2021

10 Best New Boat Accessories at IBEX 2021 2022 Sea-Doo Switch Pontoon Boat Lineup Unveiled

2022 Sea-Doo Switch Pontoon Boat Lineup Unveiled BRP Enters Fishing Boat Market with Purchase of Alumacraft Boat

BRP Enters Fishing Boat Market with Purchase of Alumacraft Boat Volvo Commits To Electric Power By 2021

Volvo Commits To Electric Power By 2021 Kemimoto 4 Bow Bimini Top and Boat Bumper Review

Kemimoto 4 Bow Bimini Top and Boat Bumper Review Starweld Victory 20 Review

Starweld Victory 20 Review Princecraft Ventura 23 RL Review

Princecraft Ventura 23 RL Review Lund 2075 Pro V Review

Lund 2075 Pro V Review Scout 281 XSS Review

Scout 281 XSS Review Fuel Saving Tips For Boaters

Fuel Saving Tips For Boaters Best Boating Accessories

Best Boating Accessories Best Boating Apps

Best Boating Apps 5 Pontoon Boats That Are Made To Fish

5 Pontoon Boats That Are Made To Fish 10 Great Small Pontoons

10 Great Small Pontoons Your Boat Was Expensive—Do You Really Trust a $2 Rope From the Dollar Store to Secure It?

Your Boat Was Expensive—Do You Really Trust a $2 Rope From the Dollar Store to Secure It? Do I Need Insurance Coverage Against Ice or Freezing Damage?

Do I Need Insurance Coverage Against Ice or Freezing Damage? What Kind Of Insurance Coverage Do I Need?

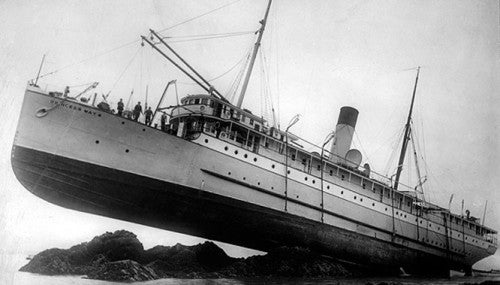

What Kind Of Insurance Coverage Do I Need? What About Salvage?

What About Salvage? Boat Insurance or Yacht Insurance?

Boat Insurance or Yacht Insurance?

The Best Bowriders For The Money

The Best Bowriders For The Money

Sailfish 312CC Review

Sailfish 312CC Review

The Wildest Concept Yachts

The Wildest Concept Yachts

2016 Trifecta 200 Series 220FCR

2016 Trifecta 200 Series 220FCR 2016 Harris Grand Mariner SL 270 DL

2016 Harris Grand Mariner SL 270 DL 2016 Crestliner Authority 2050

2016 Crestliner Authority 2050 2016 Harris Grand Mariner SL 230 DLDH

2016 Harris Grand Mariner SL 230 DLDH